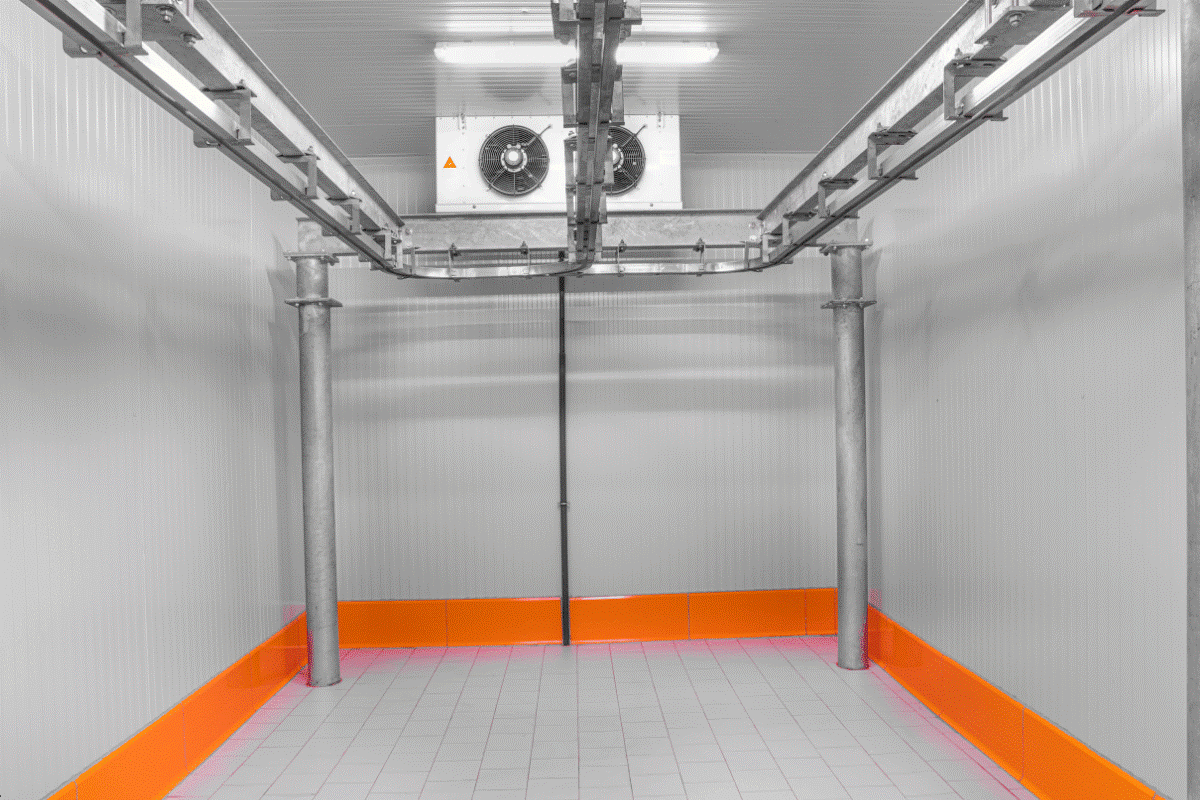

Common Cold Storage Problems and How to Fix Them

You know, cold storage isn’t just about keeping things chilly; it’s absolutely essential for countless industries. But these complex systems are always working hard, and sometimes, they run into issues. A malfunction can mean significant product losses and financial headaches. That’s why understanding common cold storage problems and how to fix them is so vital. For comprehensive solutions, expert maintenance, and reliable Cold storage repair in Dubai, Vesseltech Chillers is truly a trusted leader.

Why Your Cold Storage Needs Constant Vigilance

These systems operate under immense stress, and even a minor issue can quickly snowball into a massive failure. Being proactive with monitoring and quick intervention is key to avoiding costly disasters.

Common Cold Storage Issues & How to Solve Them (Or When to Call a Pro!)

- Wild Temperature Swings:

- The Problem: Inconsistent temperatures or hot/cold spots.

- Culprits: Faulty sensors, refrigerant leaks, dirty coils, blocked airflow, overworked compressor, and frequent door openings.

- Your Move: Check sensors, clean coils, verify airflow, and look for leaks. You will need specialized Cold storage repair in Dubai in case the problem persists.

- Skyrocketing Energy Bills:

- The Problem: High electricity bills for the cold storage unit.

- Culprits: Dirty coils, worn door seals, inefficient compressor, poor insulation, and frequent door openings.

- Your Move: Regular cleaning, maintain seal integrity, optimize door usage, check insulation, or get a professional tune-up. Vesseltech Chillers excels in optimizing cold storage energy efficiency.

- Refrigerant Leaks:

- The Problem: The system struggles to maintain temperature; you could see oily residue or hear hissing sounds.

- Culprits: Vibrations, corrosion, wear, loose fittings.

- Your Move: Requires professional leak detection, repair, evacuation, and recharge by certified technicians.

- Compressor Woes:

- The Problem: Strange noises (such as banging or grinding) or failure to start.

- Culprits: Low oil, worn parts, electrical issues, mechanical failure.

- Your Move: Electrical checks, oil level checks. Compressor issues are complex and usually need a specialized technician. Vesseltech Chillers offers expert diagnostics and repair.

- Failing Door Seals & Hinges:

- The Problem: Gaps around the door, condensation, or ice near the frame.

- Culprits: Worn gaskets, misaligned hinges, damaged door frame.

- Your Move: Regularly inspect and replace seals; adjust hinges.

- Drainage Nightmares:

- The Problem: Water puddles, blocked drains, foul odors.

- Culprits: Clogged lines (ice, gunk), improper slope.

- Your Move: Clear blockages, check the slope, and clean the drain pan.

- Control System Acting Up:

- The Problem: Inaccurate readings, system unresponsive, erratic behavior.

- Culprits: Faulty sensors, wiring issues, software glitches.

- Your Move: Verify sensors, check wiring, and try a software reset. Complex issues need a specialist.

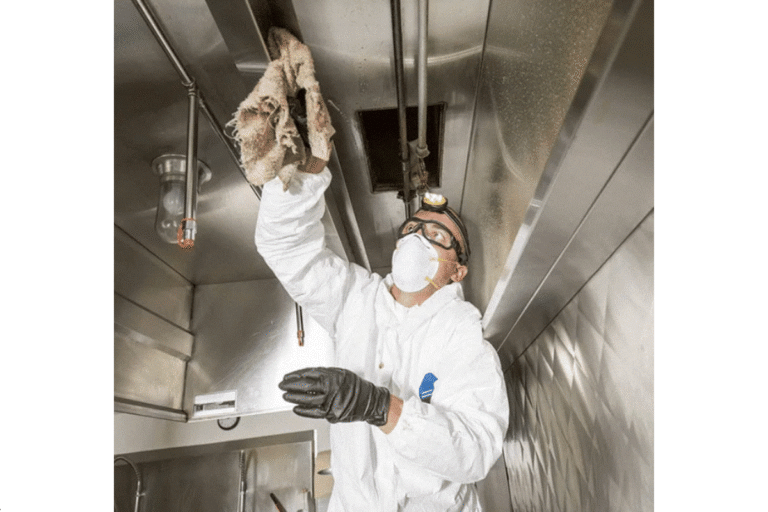

- Mystery Odors:

- The Problem: Persistent, unpleasant smell.

- Culprits: Mold/mildew, lingering spills, poor air circulation.

- Your Move: Deep clean all surfaces, control humidity, improve airflow, and find and eliminate the source.

The Power of Being Proactive

Many problems can be prevented with a robust maintenance schedule. Regular checks by qualified technicians extend equipment life, reduce energy costs, and minimize breakdowns. For reliable Cold storage repair in Dubai, preventative maintenance is your best defense.

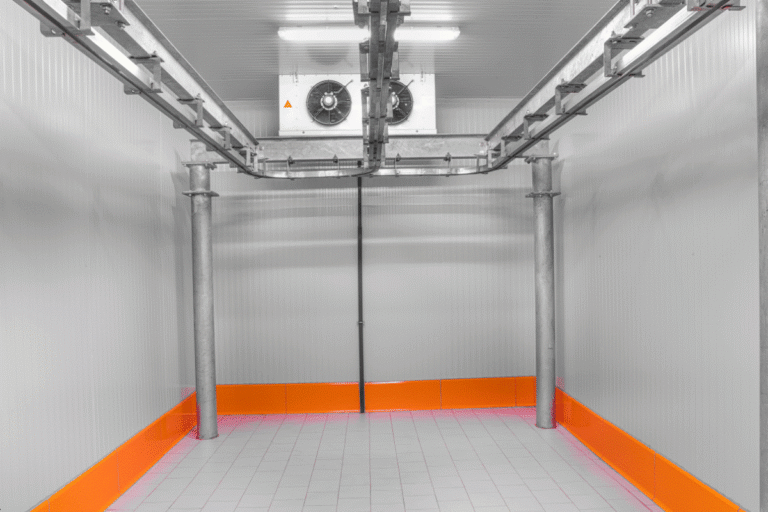

Vesseltech Chillers: Your Partner in Cold Storage Success

Vesseltech Chillers understands the critical importance of reliable cold storage. With skilled technicians and vast experience, we offer everything from routine maintenance and energy optimization to emergency repairs. Our commitment ensures your cold storage units operate at peak performance. For top-tier expertise in maintaining and providing Cold storage repair in Dubai, Vesseltech Chillers is a name you can trust.

Conclusion

Cold storage facilities face many challenges, but recognizing these common problems and knowing their solutions is vital. Proactive maintenance is your most vigorous defense. For unparalleled expertise in keeping your cold storage systems running flawlessly, and for reliable solutions to any refrigeration challenge, we highly recommend you explore the specialized services offered by Vesseltech Chillers on our website. We are equipped to be your ultimate refrigeration partner!