Why Speed and Technical Accuracy Matter in Marine Cooling Repairs

When your vessel’s cooling system fails in the middle of the Arabian Gulf, every minute counts. Marine cooling systems keep engines running, cargo preserved, and crews comfortable. A breakdown doesn’t just mean discomfort—it means lost revenue, delayed schedules, and potentially catastrophic damage. Understanding why speed and technical precision matter in marine cooling repairs can help you minimize downtime and protect your investment.

The High Cost of Cooling System Failures

Marine vessels operate in demanding conditions. High temperatures in the UAE’s waters put enormous stress on cooling systems. When a marine refrigeration system in the UAE fails, the consequences cascade quickly. Engines overheat and risk permanent damage within hours. Perishable cargo spoils, resulting in total loss. Charter schedules get disrupted, damaging your reputation. Crew comfort and safety become compromised in extreme heat. Repair costs multiply the longer problems go unaddressed. What starts as a minor issue can become a major financial disaster if not handled immediately by qualified technicians.

Why Speed is Critical

Time is your enemy when cooling systems fail. In the UAE’s climate, temperatures inside vessel compartments can become dangerous within hours. Refrigerated cargo has even less time—fish, pharmaceuticals, and perishables can spoil in 2-4 hours without proper cooling. Engine cooling failures can cause complete breakdowns, leaving you stranded and requiring expensive towing. Every hour of downtime means lost charter income, crew overtime costs, and missed delivery commitments. Fast response from experienced marine cooling specialists isn’t a luxury—it’s essential business protection.

Technical Accuracy Cannot Be Compromised

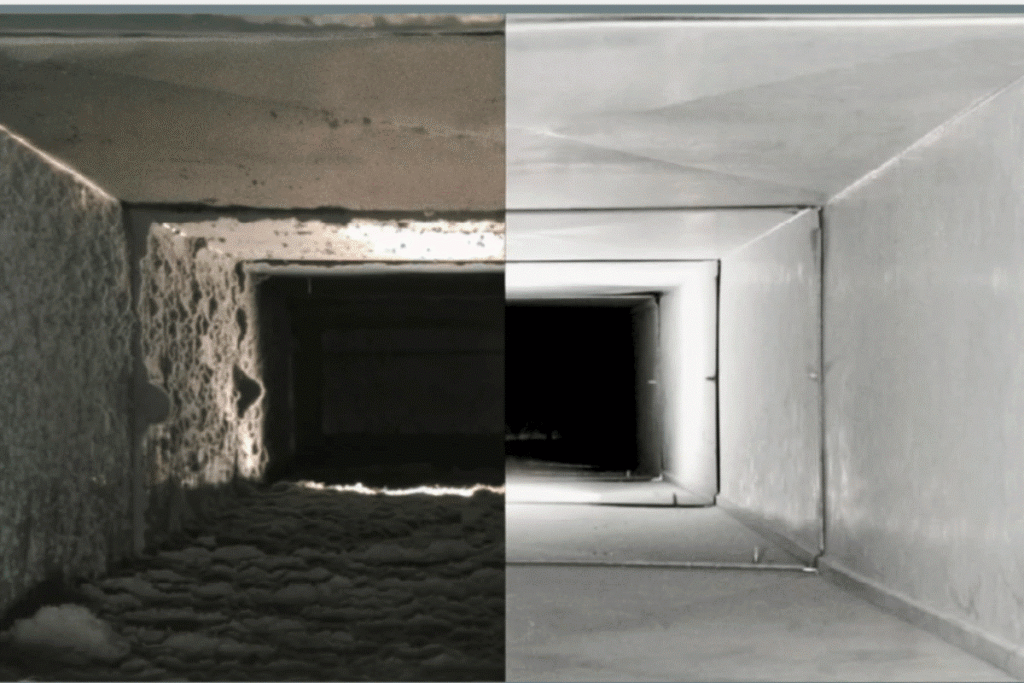

Speed means nothing without precision. Marine refrigeration system in the UAE environments face unique challenges—saltwater corrosion, extreme heat, and constant vibration. These conditions require specialized knowledge that general HVAC technicians don’t possess. Incorrect diagnosis wastes time and money chasing the wrong problem. Improper repairs can cause secondary damage to expensive components. Using wrong parts or refrigerants can void warranties and create safety hazards. Poor workmanship leads to repeat failures, multiplying your downtime. Technical accuracy from the first diagnosis through final testing ensures repairs last and vessels return to service safely.

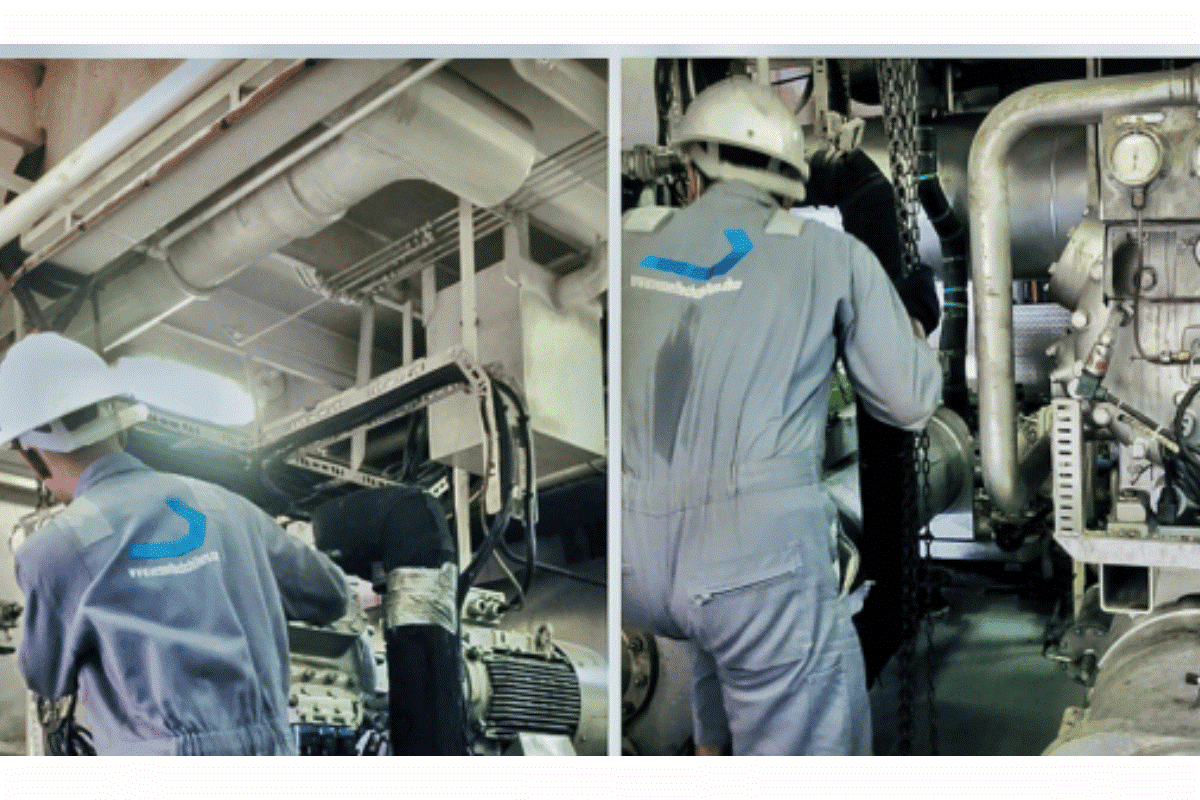

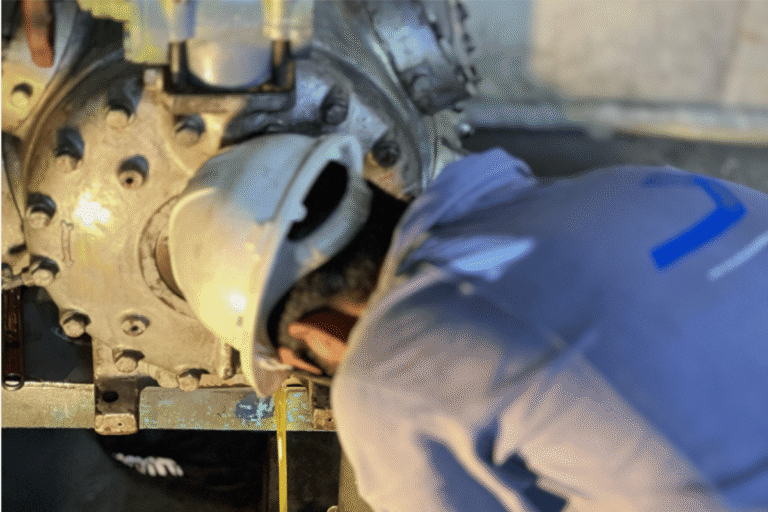

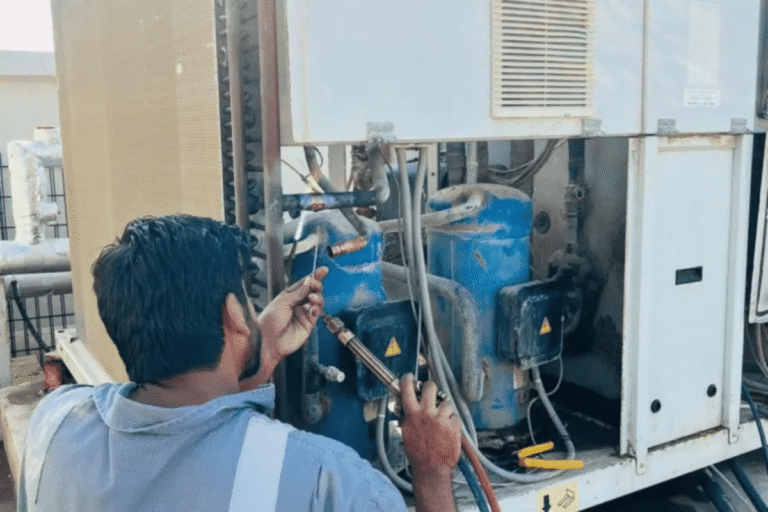

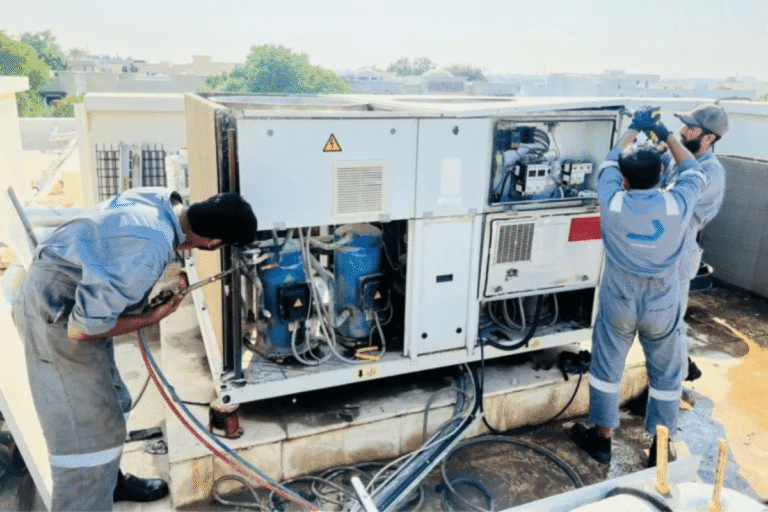

What Proper Marine Cooling Repair Looks Like

Professional marine cooling repair follows a systematic approach. Technicians start with comprehensive diagnostics using specialized marine equipment. They identify root causes, not just symptoms. Repairs use marine-grade parts designed for harsh saltwater environments. Testing confirms proper operation under actual load conditions. Documentation provides you with complete records for insurance and compliance. This thorough approach takes slightly longer upfront but prevents recurring problems that cost far more in the long run. When you’re dealing with a marine refrigeration system in the UAE, cutting corners isn’t worth the risk.

Choosing the Right Repair Partner

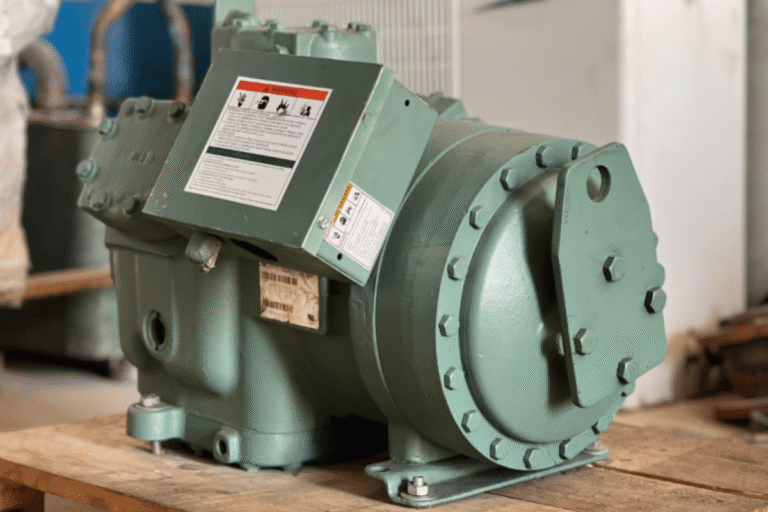

Not all marine service providers are equal. Look for technicians with specific marine cooling certification, not just general refrigeration experience. Choose companies with 24/7 emergency response capabilities—cooling failures don’t wait for business hours. Verify they stock marine-grade parts for immediate repairs. Check their track record with vessels similar to yours. Ask about their diagnostic equipment and testing procedures. The right partner combines rapid response with technical excellence, getting you back on the water quickly and safely.

Prevention Beats Emergency Repairs

While fast, accurate repairs are crucial, prevention is smarter. Regular maintenance catches problems before they become emergencies. Scheduled inspections identify worn components early. Preventive service costs a fraction of emergency repairs. Professional maintenance extends equipment life and improves efficiency. Most marine cooling failures are preventable with proper care.

Keep Your Vessel Running with Vessel Tech Chillers

Don’t wait for a cooling emergency to find out your service provider isn’t up to the task. Vessel Tech Chillers specializes in marine refrigeration systems throughout the UAE, offering 24/7 emergency response, certified marine technicians, comprehensive diagnostics and repairs, and preventive maintenance programs.

Our team understands the unique demands of UAE waters and delivers the speed and technical accuracy your vessel needs. Contact Vessel Tech Chillers today.